What is Constant Power and How Does it Work?

Programmable DC power supplies have historically been characterized by a point rating power output capability in Watts. Point rated implies that maximum available power output from the power supply is available only at one operating point. This power output point is where both DC voltage and DC current output are both at the maximum setting of their respective available ranges. For example, a 10kW supply with a 0 ~ 250Vdc voltage range can supply 10kW output only when the load current is 40Adc. The implication of this way of designing programmable DC power supplies for the end-user are twofold:

1. The power supply selected invariably has to be sized larger than the actual power requirement of the unit under test. Thus, most of the time the power supply is used below its maximum power, voltage and/or current rating.

2. Once selected, the range of applications where the DC supply can be used are limited by both power and voltage range. In the previous example, the 250Vdc power supply cannot be used for any application that requires more than 250Vdc output.

Because of this point rating, manufacturers of programmable power supplies offer a large number of voltage range models in a given power supply model range, sometimes as many as 20 different voltage ranges for one model series. This obviously limits their ability to benefit from economies of scale in manufacturing resulting in high product cost and thus end-user pricing. End-users have had to live with these limitations for decades but new developments in power conversion technology are eliminating some of these restrictions.

Constant Power Range Design

Figure 1: DCS360-80-4 DC Power Supply

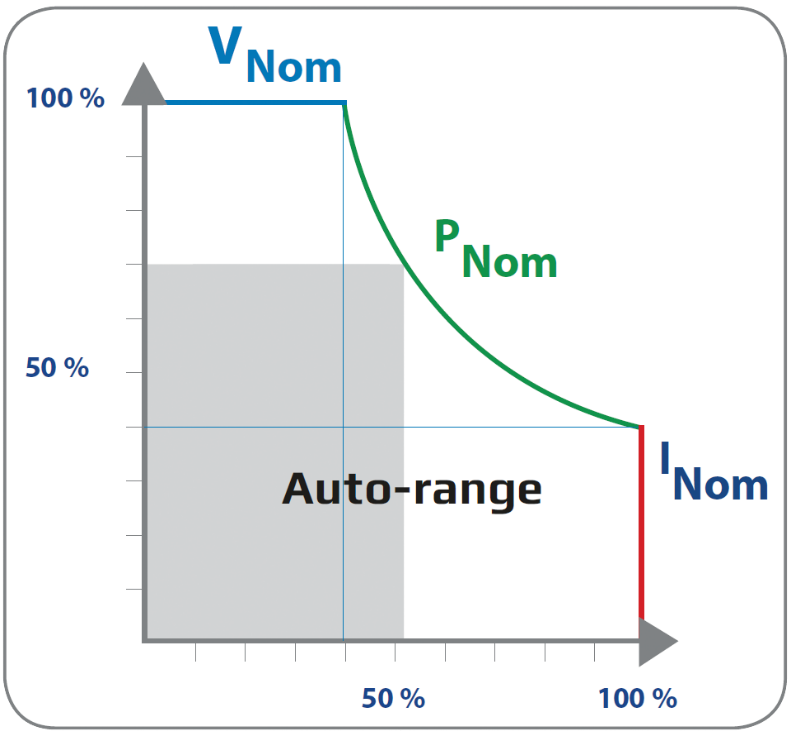

By using higher precision circuits and increased resolution control and measurement technology, the most advanced programmable power supply design no longer force the end-user to select from a wide range of point rated models. Instead, these new power supplies offer a wider voltage and current range – in some cases with a three to one ratio for both – at a given power level. A good example of this is the Adaptive Power Systems DCS Series of constant power programmable DC supplies. Voltage and Current ranges on DCS supplies are not defined by the single maximum power output set point but instead available over a wide range of setting. For example, the 10kW DCS360-80 model offers a 0 ~ 360Vdc voltage range while as the same time supporting a 0 ~ 360Adc current range, all at a maximum power output of 10kW. Thus, it could easily support the original requirement from section1.0 for 250Vdc @ 40Adc, but also a 360Vdc output at 10,000/360 or 27.78Adc and a 166.67Vdc @ 60Adc requirement. Thus, the same DC power supply supports a much wider range of applications.

Figure 2: DCS Series Constant Power Auto Ranging

Cost Savings of Constant Power Range DC Supplies

Example 1: Telecom DC / DC Converter Testing

Figure 3: 1600W DC/DC Converter

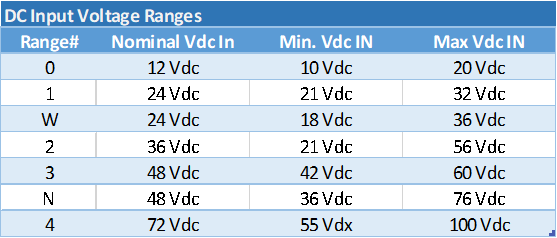

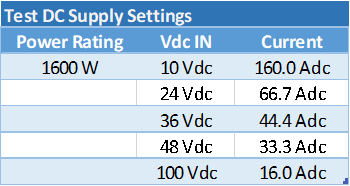

Table 1: DC/DC Converter Input Voltage Ranges

Table 2: Required Test Voltages and Current by Range

Table 3: Available Point-Rated 100V DC Supplies

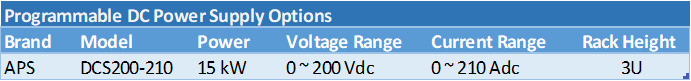

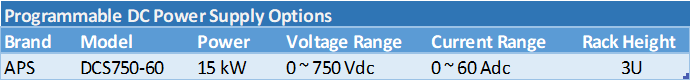

Table 4: APS Constant Power DC Supply

Example 2: PV Inverter Testing

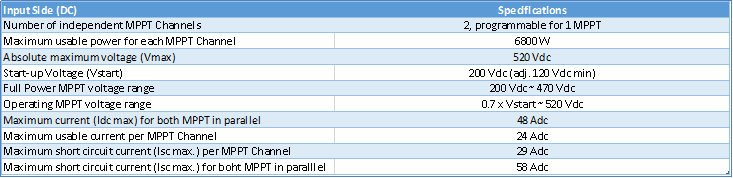

Table 5: PV Inverter DC Input Specifications

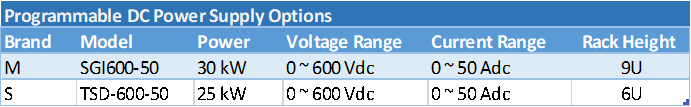

Table 6: Available Point-Rated 600V DC Supplies

Table 7: APS Constant Power DC Supply

Summary

Modern design constant power DC power supplies like the APS DCS Series save money and space in may test applications. They also provide more flexibility in R&D labs as the same DC supply can support a much wider range of voltage and current combinations than conventional point-rated DC power supplies.

For technical information and overview of available voltage, current and power combinations of DCS Power Supplies, see the product information page at https://adaptivepower.com/products/dc-supplies/DCS-series/ or call Adaptive Power Systems toll free at +1 (866) 517-8400.