Remote Control

Computer control of test equipment – including AC and DC power sources – is a critical requirement for building automated test systems (ATE) and to a lesser extend engineering development lab experiments. Key requirements for this type of computer control are:

- Reliable communication to reduce or eliminate communication errors

- Data transfer speeds

- Industry standards to support long term use of ATE systems, especially in defense applications

- Equipment interoperability to allows ATE system maintenance and upgrades

- Cost and availability

IEEE488 Standard

Historically, the IEEE488 interface bus (aka GPIB) has been the de-facto interface standard for this purpose. Established in the late 1960s by Hewlett-Packard – currently Keysight – as the Hewlett Packard Interface Bus or HPIB, this standard was eventually adopted as an IEEE standards and is commonly referred to as GPIB for General Purpose Interface Bus. Although it initially saw some use in early computer and peripheral applications, it was quickly replaced by faster and less expensive interface standards in the computer space so “GP” is somewhat of a misnomer these days.

It did thrive in the test equipment space however due to it’s tightly controlled technical specification which made it possible to mix test equipment from many different manufacturers and its support of specific ATE or instrumentation specific functions like SQR and serial or parallel polling of instruments.

Applicable GPIB Standards

The original HP specific standard has evolved through a series of IEEE and European IEC standard efforts over the years culminating in the 2004 version. Over objections from HP, it now also includes the HS-488 higher speed data transfer mode contributed by National Instruments in an effort to address the relatively low data transfer speed of the original HPIB interface.

The current 2004 IEEE/IEC standard IEC 60488-1, Standard for Higher Performance Protocol for the Standard Digital Interface for Programmable Instrumentation – Part 1: General,[10] replaced both older IEEE 488.1/IEC 60625-1, and IEC 60488-2,Part 2.

GPIB Pro’s and Con’s

There are benefits and drawbacks to GPIB, specifically:

Benefits

Benefits

- Proven, reliable communication interface dedicated to test equipment computer control applications.

- Has been supported for long periods of time (45+ years)

- Native hardware handshaking and hardware control for Remote/Local, Serial Parallel Poll and Service requests provided higher level of control than serial based interfaces like USB or LAN that require these functions to be added in software layers.

There are also obvious drawbacks to consider:

Drawbacks

Drawbacks

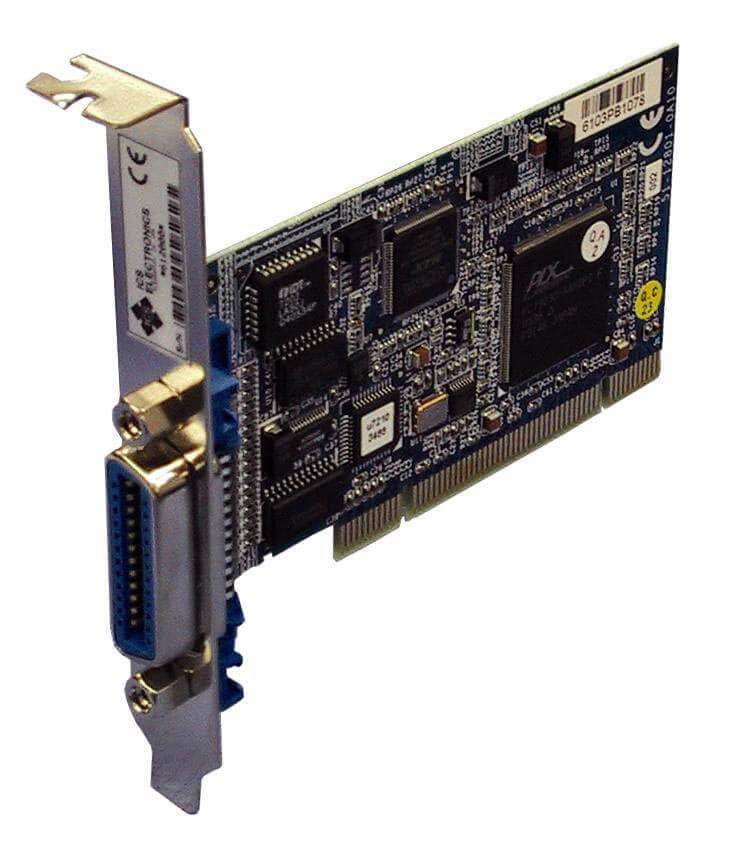

- The GPIB interface is a parallel bus which requires 24 signals including ground and shield and special shielded cabling and connectors. These cables are expensive and fairly limited in length. The required Centronics style 24 pin connector is large by today’s standards posing problems for 1U full or half rack size test equipment as the GPIB connector takes up a significant portion of the available rear panel.

- The number of instruments supported is theoretically limited to only 30 but in practice far fewer as the total cable length to all instruments connected is limited as well.

- The cost of the required GPIB controller and associated cabling is very high compared to modern interfaces like USB and LAN.

- The cost of implementing a fully compatible GPIB talker/listener in piece of test equipment is considerably higher than that of USB or LAN, adding to the cost of the test equipment. For less expensive test equipment, this cost adder can be considerably compared to the cost of entire instrument.

- Many GPIB controllers were based on computer bus standards such as ISA, PCI or PCIe which have since disappeared. This can make it more difficult to get GPIB controllers in the future as new computers increasingly rely on serial type interface like USB, Thunderbolt and LAN.

- Sole source for PC based GPIB controllers. Most manufacturers of GPIB controllers other than National Instruments have disappeared due to the dwindling market for these controllers.

USB and LAN as alternatives?

From a cost point of view, using USB or LAN in place of GPIB for instrument control seems like an obvious choice. However, several of the functions provided by GPIB for control and management of the test equipment are missing and have to be implemented in some other way. This means a simple USB or LAN approach is not a true replacement in ATE applications.

Obvious benefits of USB and LAN of course jump out immediately:

- Must faster data transfer speeds. Even accounting for the parallel nature of GPIB which carries one byte at a time versus one bit at a time and allowing for HS-488 8x theoretical speed increase over basic GPIB, modern USB-3 and LAN speeds of 5 Gb/sec… and 10Gb/sec respectively provide data rates that are orders of magnitude higher.

- USB and LAN are ‘essentially’ free on any PC or other computer device. The cost of USB and LAN on the test equipment itself is small as well compared to the required GPIB talker/listener logic and connector.

- Lack of ATE specific functions like SRQ, ATN, Device Trigger and Parallel or Serial Poll on USB and LAN vs GPIB standard often requires additional protocol layers to be added, most of which are not standardized.

- USB is a point to point interface, not a star topology so communicating with multiple instruments requires multiple USB ports or hubs

- LAN is a shared interface so data transfer rates are affected by the number of instruments connected to the same segment or computer.

- Connecting test equipment to a company network exposes them to the potential risk of unauthorized remote access. In the case of a power source, this can be a great risk to the safety of employees working on the ATE systems. Using an isolated, dedicated local LAN segment is the best way to mitigate this. Some test equipment like Pacific’s AFX series provides user access control provision to ensure security on networks.

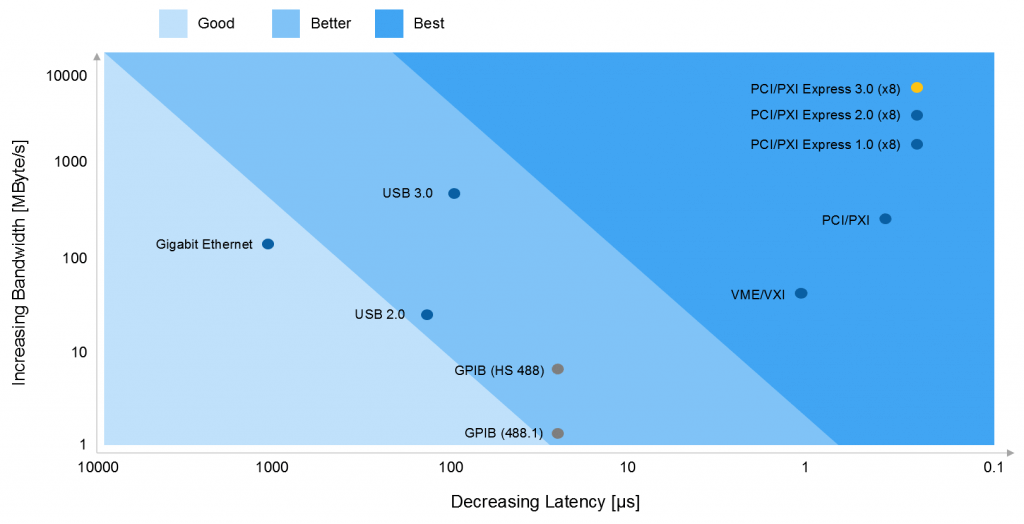

Speed and Latency Benchmarks

Several benchmarks have been done to compare overall throughput between GPIB, LAN and PXI. While PXI offers many speed advantages, the small form factor and severe lack of power and cooling as required for programmable power sources renders it unsuitable for power test equipment.

Some results are shown in Figure2 below. Note that data transfer rates and latency are only one aspect of overall ATE performance and other factors such as long-term support, cost and ease of integration should be weighed as well when selecting an interface solution.

LXI Standard

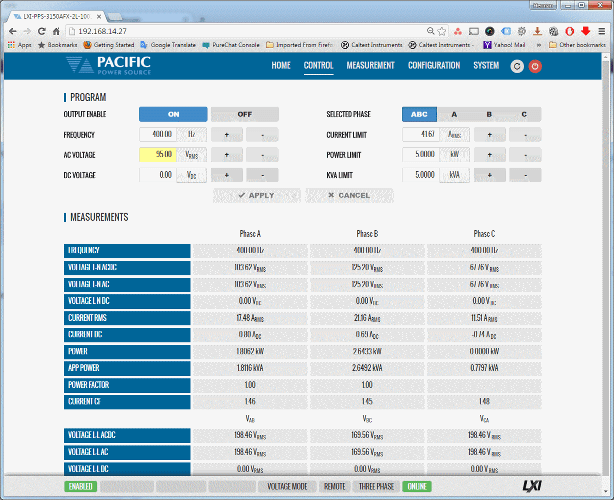

The LXI standard was developed by a consortium of test equipment manufacturers to address some of the issues associated with using LAN in ATE systems to control test equipment. This LXI standard which stands for “Lan eXtension for Instrumentation” has been in place since 2005 and is actively supported by the LXI consortium. (https://www.lxistandard.org/ )

The LXI standard for LAN equipped instrumentation helps reduce the time it takes to set up, configure, and debug test systems. LXI is an open, accessible standard based upon Ethernet that identifies specifications and solutions related to the functional test, measurement and data acquisition industries. Here are some key benefits of using LXI to build Test Systems:

- Leverages the telecommunication industry infrastructure

- Lowers test system cost using ubiquitous and inexpensive LAN components

- Simplifies system integration

- Provides high performance

- Ensures broad instrument availability

- IVI Driver requirement standardizes look and feel between products

- Built-in Web Server for remote access and control of device

Why Does it Matter?

The GPIB bus standard is getting very old and support for it is diminishing. Many new instruments no longer offer a GPIB interface. This trend is likely to continue as faster, less expensive interfaces used in TI and the Computer industry have far more funding and development resources devoted to them.

Pacific Power sources offers the GPIB interface as an option on all of its power sources. On new generation models like AFX series, LXI/LAN is included as a standard interface along with USB.

Conclusion

When selecting a programmable power source, either AC and or DC, consider the availability of LXI when planning use in ATE systems now of in the future. Of source, combinations of several bus solutions like GPIB, USB and LAN are possible but for reasons of cost, ease of integration and long term support need to considered carefully.